Latest OCS News

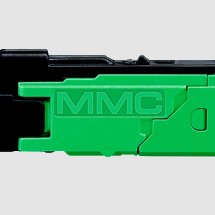

March 2024 - Certified to make MMC Assemblies

OCS is ready to terminate the new US Conec MMC Connectors for you. We are now certified by US Conec and we have invested in additonal equipment to meet your MMC needs. See more about the MMC from US Conec on their website.

Click here to see the certificate

OCS can build your fiber optic cable assemblies, contact our representatives at 972-331-4627 or email us!!

September 2023 - Evaluation of Epoxy Curing Processes

A core process which we will soon be improving is the curing of epoxy within connectors. This process secures the optical fiber within the ceramic ferrule and connector. We will be replacing a significant portion of our ovens with new ovens from Connected Fibers which will allow us to select a temperature, maintain that temperature, and see that temperature visually from across the room.

OCS can build your fiber optic cable assemblies, contact our representatives at 972-331-4627 or email us!!

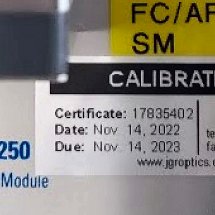

November 2022 - Evaluation and Calibration of Loss Modules

Every year we calibrate our JGR and EXFO testing centers. We do complete calibration, tuning, and maintenance on this important equipment. We usually have between 14 and 16 modules to calibrate. Representatives of JGR Optics, once again flew in from Canada and completed the task.

Our customer service representatives are available by phone or email. Call us at 972-331-4627 or email us!!

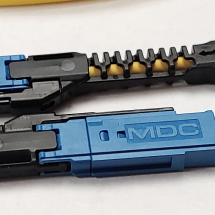

May 2022 - Evaluation of MDC Connector

A random sample from a recent production run of the MDC® VSFF connector has been evaluated for us by the manufactuer, US Conec®. After analysis our samples were observed to be within specification for all aspects evaluated. We would be happy to tell you more about the MDC.

Our representatives are available by phone or email. Call us at 972-331-4627 or email us!!

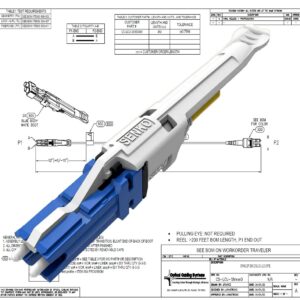

April 2022 - Yet Another New Connector

We have new pre-productions plans for another VSFF connector underway. We are ready to make our pre-production order of Senko® CS® Connector. This is not the last of it, we are planning on adding another VSFF (Very Small Form Factor) connectors in addition to the CS® very soon. This connector is about 40%the size of an LC connector.

Our representatives are available by phone or email. Call us at 972-331-4627 or email us!!

March 2022 - New Connector

We have made our first pre-production orders of the new US Conec® ELiMENT™ MDC Connectors. We are planning on adding other VSFF (Very Small Form Factor) connectors to our capabilities very soon. We have terminated Single Mode MDC jumpers to 1.6 mm cable. The MDC connector is almost half the size of an LC connector with twice the number of ferrules.

Our representatives are available by phone or email. Call us at 972-331-4627 or email us!!

December 2021 - Custom Metal Order

Everything we make is to our customer's design. Sometimes we have to help. This time we had special reels made for a 2RU rack mount product manufactured to a customer design. Here we see the first product taking shape as the manufacturing team works with the engineering team to meet the challenge.

Our representatives are available by phone or email. Call us at 972-331-4627 or email us!!

October 2021 - IL/RL Module Calibration

Calibration of our JGR and EXFO testing centers has just been completed. Every year we do complete calibration, tuning, and maintenance on this important equipment. Representatives of JGR Optics, once again flew in from Canada and completed the task.

Our customer service representatives are available by phone or email. Call us at 972-331-4627 or email us!!

March 2021 - Shopping for Reels

As a custom manufacturer, many of our customers supply us with their own reels, but others rely on us to provide reels. Our purchasing staff has been working very hard idendifying new sources and new ways to obtain reels for our customers who rely on us. Like so many things, the Covid-19 pandemic has affected supplies. Currently we are meeting demand.

Would you like Optical Cabling Systems to OEM your cable assemlies? Our customer service is available by phone or email. Call us at 972-331-4627 or email us!!

November 2020 - 432 Fiber 12 Position MTP® Cable

We make thousands of MTP® assemblies every year. This week we are terminating several 432 fiber cable assemblies with 12 fiber MTP®connectors. Both ends are identical fanouts and each leg is configured as Type B. We provide our customers with a nearly infinite variety of cable trunk and breakout configurations in standard and non-standard polarities.

Our customer service is available by phone or email. Call us at 972-331-4627 or email us!!

October 2020 - Equipment Calibration amid the Pandemic

Our annual calibration of our JGR and EXFO testing centers was delayed due to the current Pandemic. It is imperative to do complete calibration, tuning, and maintenance on this important equipment. Representatives of JGR Optics were finally able to fly in from Canada and complete the task. Travel restrictions, airline shut downs, and quaranteen requirements were a huge factor in planning this year's very important event.

Our customer service is available by phone or email. Call us at 972-331-4627 or email us!!

June 2020 - Operating Safely During the Pandemic

We continue to be open during the pandemic. Our employees continue to be cautious amid the pandemic, wearing masks and disinfecting are a way of life during these times. As a reminder to our customers, we are operating at full capacity and continue to fulfill orders just as before.

Our customer service is available by phone or email. Call us at 972-331-4627 or email us!!

April 2020 - Being Careful

We have become ever more cautious with the presence of the Covid-19 virus. We are open for business and manufacturing, but are screening employees for temperature at the door, wearing masks, and distancing.

Our customer service are also available by phone or email. Feel free to call or email us.

December 2019 - Slimpac-Type A Cassettes

Just this week (12/30) we are completing an order for nearly 1000 Slimpac Type A Cassettes. These cassettes take up less space than a regular cassette.

You can contact Optical Cabling Systems for more information.

July 2019 - New Connector Tryout

Just this week (7/30) we terminated a sample of a new MTP® brand connector to a 3.0 mm loose tube cable. The product is designed to connect to a regular MPO adapter at a 45 degree angle for cable management purposes.

The connector is made by US Conec. US Conec Website Link

You can also contact Optical Cabling Systems for more information.

April 2019 - Annual Equipment Calibration

Again this year OCS has opted to have the insertion and return loss measuring equipment calibrated by the equipment manufacturer. Our automated EXFO and JGR measurement equipment is now good for another year of accurate IL/RL testing.

The equipment manufacturer ensures that the equipment is not only calibrated, but that PM is also done as part of the process. This, along with our encircled flux measurement methods provide our customers with accurate IL/RL measurements of both single mode and multi-mode products.

Calibration of our other equipment occurs within the same time frame.

November 2018 - Customer Stocking System

Optical Cabling Systems has established an improved JIT stocking program for certain customers. Selected products that a customer needs shipped from stock on short notice are identified and stocked at agreed to levels.

Although 95% of what we make are made to order at the time of requirement, some quick turn products need to be stocked to meet the demands of our customers. Program details are worked out with your customer representative. Various component supplyside systems are also in place to meet customer requirements.

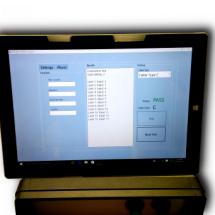

August 2018 - Barcoding Project Continues

Optical Cabling Systems is increasing the use of barcoding to track a number of processes, including inventory management and production. Each product is tagged with a unique barcode which is utilized during production to identify the product.

Although each tag is only used for the duration of production and is destroyed when the product is completed, the tag eliminates and reduces paperwork in other areas while increasing accuracy in identifying each product for various testing and other process steps.

May 2018 - Certified to ISO 9001:2015

ISO 9001 has changed with the introduction of the newest version ISO 9001:2015. ISO standards are reviewed every five years. If a need is found the standards are revised which helps to ensure the standard remains relevant to the current business environment.

This year Optical Cabling Systems updated to the new standard. The new standard changes some of the underlying structure, but the main difference is emphasis on risk based thinking.

April 2018 - Calibration and Maintenance of IL/RL Test Sets

For the past three years OCS has opted to have the light loss measuring equipment portion of our annual calibrations completed by the equipment manufacturer. OCS relies on EXFO and JGR loss measurement equipment for our IL/RL testing.

By having the equipment manufacturer do this work, the units are truly calibrated and repaired. PM is also done as part of the process.

All equipment was found to be in tolerance when tested and the machines are ready for another year of use.

April 2017 - Last ISO 9000-2008 Quality Audit

OCS just completed the last ISO 9001:2008 quality audit it will ever have. Next year our switch to ISO 9001:2015 will be complete and we will be audited against the new standard.

ISO 9001, of course, is a well known standard which defines requirements for a company's quality management system (QMS). The new version of the standard is ISO 9001:2015 which will replace ISO 9001:2008. The new standard is designed to lower risk, or at least focus more on risk based thinking.

January 2017 - New Cable Label Printers

The cable label printers at OCS have been replaced. The old printers had reached a point where it was time to either replace the printing heads or replace the printers. After review, replacement was the optimal choice.

As of this month, after six weeks of changeover activities, trials, and training, the entire cable label printing system has been replaced with two new Brady printers which are capable of printing all current labels, and more.

In addition to new printers a new computer workstation running the latest Brady LabelMark™ software package was installed. The new system has been added to our network which will allow additional method improvements in the future.

These printers are capable of a wide range of barcodes, simple black and white graphics, and a full range of font types and sizes. One of the most important improvements is in crispness and clarity of the printing.

November 2016 - New JGR™ MPO Polarity Tester

OCS has worked with JGR Optics™ to develop a new polarity tester and we have now purchased a 24 channel polarity verification unit. The machine allows us to automatically identify 12 fiber Method A, B, or C polarity, but goes bey0nd that with 24 fiber route identification.

In addition to standard configurations, such as 100G (which is based on 24 fiber MPOs) we use this system to accurately verify that cable fibers are correctly routed for a wide variety of special customer configurations in trunks and fan-outs.

With the addition of a second unit this workstation can be updated to handle 48 fiber MPO polarities, again with the ability to check any available route.

August 2016 - Polarity Tester Prototype Development

OCS is testing a new JGR Optics™ 12 channel polarity verification unit. The unit is a one of a kind prototype and it quickly identifies MPO® cable polarity as Method A, B, or C automatically.

Today, however, we also have to verify that cable fibers are correctly routed for a wide variety of special customer needs and this new test machine can be programmed for literally any fiber route. We will be using this unit going forward to replace older polarity checking methods with greater speed and accuracy.

JGR has been working closely with us to identify needs and may even design a 24 channel unit to more closely match today's MPO cable configurations.

July 2016 - Website Upgrade

The latest change at OCS is a face-lift for our online presence. Our website was previously a simple HTML website, but it has been upgraded to a modern WordPress database powered website. This software will allow us to add content more easily and to add features in the future with greater ease.

The software being used is very popular among business users. There are a large number of website publishing platforms out there, but a recent survey has shown that 25% of all websites on the internet are published using the WordPress software.

March 2016 - MPO Cleaving System

Our newest MTP® production equipment addition is the PHENIX MT cleaving system. This system allows us to cleave 4 to 72 fiber MPO/MTP® ferrules quickly and accurately. The system can complete an entire MT ferrule cleave in seconds. The time is comparable to that of a laser cleaving system and the quality of cleave is excellent. The mechanical cleaving method of this machine does not have any heating effects when the cutting is effected.

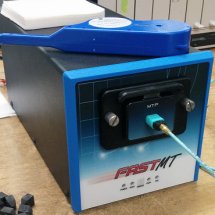

July 2015 - FastMT

The newest addition to our roster of test equipment is the FastMT inspection system. This system allows us to visually inspect from 4 to 72 individual fibers in MPO/MTP® ferrules to standards or customer specifications with reproducible results quickly and accurately.

December 2014 - Production Floor Remodel

The remodel of our production floor is completed with a whiter brighter look and a more controlled environment. In addition to adding space, power supply and lighting was increased. Additional changes include hard, cleaner surfaces, both on the floor and ceiling.

May 2012 - New Light Turn® Prizm® Connectors

Designed as a miniature detachable connector for high speed board mounted parallel optic modules. The PRIZM® LightTurn® connector consists of a multi-fiber ferrule with a photonic turn TIR lens array which accepts cleaved fibers. the terminated PRIZM® along with an accompanying connector housing attaches directly to a circuit board.

OCS spent $60,000 for training and equipment to be able to terminate and test these assemblies for our customers. The first order was delivered this month and OCS looks forward to making many more Prizm® assemblies in the future. Call or email us if you need this type of assembly for your customers and want to avoid the cost and commitment to setting up your own production area. Let us do this product for you.

2009-2010 - MTP Pioneer

OCS, an early adopter of the MTP®, received the necessary training at US Conec® allowing us to become the largest domestic supplier of MTP® assemblies in 2009 and 2010.